Industries

Heating and Industrial Processing

Emnico Fuel Catalyst is based on a patented Fitch® technology that's manufactured by Advanced Power Systems International, Inc. in the USA. The catalyst has applications for boilers, burners, kilns that use natural gas, diesel, gasoline or propane.

Emnico Fuel Catalyst allows more complete and efficient fuel burning process resulting in lower carbon build up and therefore reducing system maintenance. It also decreases the emissions of the greenhouse gases.

Applications

- · Industrial plants that require heat generation (bricks, ceramic products)

- · Boiler houses for steam or heat generation (heating systems)

- · Applicable for liquid oil or natural gas fired burners and boilers

Benefits

- · Reduce fuel consumption

- · Decrease emission of greenhouse gas

- · Improve engine horsepower and torque

- · Reduce bacteria growth

- · More complete and efficient combustion with less residue

- · Lower maintenance requirements

- · Extend engine lifetime

- · No moving parts, no additives, no magnets, no electrical hook-ups

- · Easy and simple installation

Worldwide applications

RAK Ceramics (United Arab Emirates)

Burners: 280 x Ancora 45 kW

Fuel: Natural Gas

Fuel Savings using FHD5-NG: 5.5%

Agrosuper-Santaigo (Chile) - Agrosuper, a large meat processing company in Santiago, Chile, recently installed Fitch at it's natural gas fired meat processing facility in Santiago. This plant runs 24 hours/day, 6 days a week and consumed 600 cu. meters or 21 modernizr-customF of gas/ hour. Over the first month they recorded a 5% decrease in consumption.

Power Generation

Emnico Fuel Catalyst is based on a patented Fitch® technology that's manufactured by Advanced Power Systems International, Inc. in the USA. The catalyst has applications for diesel, gasoline, natural gas or propane fired engines and turbines. Applications range from more than 50,000 HP, down to local power generators where the power grid is not available.

Emnico Fuel Catalyst allows more complete and efficient fuel burning process resulting in lower carbon build up and therefore reducing system maintenance. It also decreases the emissions of the greenhouse gases.

Applications

- · Industrial power plants

- · Gas turbines

- · Diesel power generators

- · Applicable for liquid oil or natural gas fired engines

Benefits

- · Reduce fuel consumption

- · Decrease emission of greenhouse gas

- · Improve engine horsepower and torque

- · Reduce bacteria growth

- · More complete and efficient combustion with less residue

- · Lower maintenance requirements

- · Extend engine lifetime

- · No moving parts, no additives, no magnets, no electrical hook-ups

- · Easy and simple installation

Worldwide application

CAT 3412 Gen-Set, 3412 Propulsion Engine, 3406 Gen-Set-Hawthorne Caterpillar San Diego, CA

- a. Field test on Caterpillar 3412 gen-set on a vessel in the South Pacific.

- b. Water Brake dynamometer test on a Caterpillar 3412 propulsion engine at the Hawthorne Caterpillar dealer located in San Diego, CA.

- c. Resistive/reactive load bank test on a Caterpillar 3406 powered 300 KW gen-set at the Hawthorne Caterpillar dealer located in San Diego, CA.

Results:

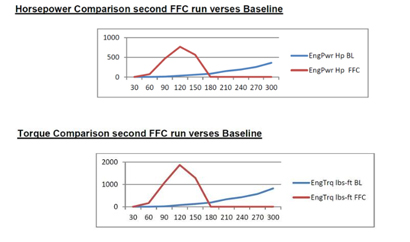

Engine performance (horsepower and torque, responsiveness and noise) benefited from the presence of Fitch treatment. The ramp mode data (2 sets with FFC verses one baseline) indicated significant fuel savings when data are normalized to horsepower and torque produced by the engine. Also, it is obvious from the comparison of the 4 sets of graphs of the ramp mode data that engine performed better with the FFC fuel. The engine reached much higher levels of torque and horsepower with the FFC treated fuel. Fuel savings were significant and well documented in all three evaluations.

25MW Turbine - Constellation Energy Baltimore, Maryland

Engine: Westinghouse 251AA 25 Megawatt diesel fired turbine Facility: Operated by Constellation Energy - Baltimore, Maryland

Results with Fitch installed -

- · Reduced Visible Smoke

- · Improved “light-off” time from 12 to 2 sec

- · Improved effective “light – off” 95% vs. 65%